About Us

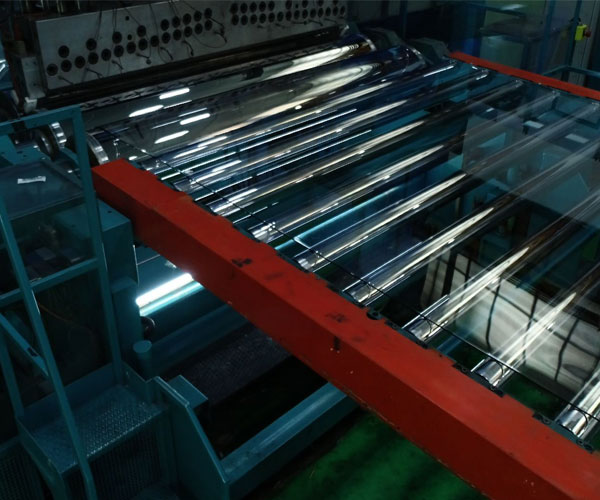

Saraswati Group of Companies, a pioneer in the agrochemicals industry, needs no introduction. In 1987, the Group forayed into the agrochemical industry and has since aspired to uplift its dynamics. To meet the desperate need for a quality supplier of polycarbonate sheets amongst the user base, Saraswati Group initiated the production of Polycarbonate sheets under the name ULTRALITETM ® . We can proudly boast of high-quality extrusion lines from Omipa and the best of raw materials from CovestroTM to re-iterate our commitment to deliver world-class quality. Besides the best in quality and advanced materials, ensuring customer satisfaction and environmental protection remains our highest priority.

Based in Jammu, Saraswati Plastotech India Pvt. Ltd. is a manufacturing company, which is promoted by the esteemed technocrat, Mr. Suraj Kumar Bansal. Under his leadership along with the board members, the dynamic associates make innovation possible and smoothly commandeer the progressive growth of the company. Today, not only does Saraswati Plastotech India Pvt. Ltd. have the highest plant capacity for manufacturing polycarbonate sheets in India, but have also acquired a major market share in the Indian sub-continent and exports market.

With a highly efficient workforce and the latest techniques, we remain at a constant pace with changing times and technology. Our core production products are Polycarbonate sheets, SpectarTM UltraliteTM Copolyester PETG sheets from Eastman Chemical, Polycarbonate – ABS Alloy & Blended sheets and Special Hi-Impact Acrylic PMMA sheets. Our products are trendsetters with unique combination of material properties like impact resistance, thermal and sound insulation, UV stabilized, etc. – making them the first choice for residential, industrial and commercial applications. Through our well-established and a far-reaching distribution network we assure the delivery of our products in every city and state.

New Product Development Cycle

Today, the global market is seeing further expansion while becoming more competitive. To remain one of the trusted manufacturers, a global supplier joins hands in partnership to work in tandem with the who’s who of the industry. The current scenario shows India emerging as one of the trusted sourcing centers for global companies, where procurement of newer products and features facilitate satisfying the customers. Under the “Make in India” program, we invest and deploy resources by engaging skilled people and outsourcing modern tools and technology. To demonstrate the same, the recent COVID-19 pandemic provided us the opportunity to collaborate with the healthcare industry experts and develop Polycarbonate Face shield, and Sanitizing Test Chamber Tunnel with Polycarbonate View Panels for primary checking of the suspected positive cases for quarantining.